Brand Name: YUTONG

Model Number: WNS

Place of Origin: Henan, China (Mainland)

Condition: New

Type: Natural Circulation

Usage: Industrial

Structure: Fire Tube

Pressure: Low Pressure

Style: Horizontal

Fuel: oil,gas,lpg

Output: Steam

Dimension(L*W*H): Customization

Weight: 0.5ton

Certification: ISO9001, CE, BV, SGS

After-sales Service Provided: Engineers available to service machinery overseas

Rated steam capacity: 0.5t-20t

Rated steam pressure: 0.7Mpa-2.5Mpa

Rated Steam temperature: 170-225

Feed water temperature: 20

Thermal efficiency: >92%

Boiler heating area: 13-448M2

Economizer heating area: 10-80M2

warranty: 2 years

Color: optional

Design fuel: Light Oil,Heavy Oil, Natural Gas,City Gas etc

Condensing gas boiler plays a significant role in the textile industry, the steam boiler is used for different processes, such as dyeing and drying, and support the use of resing finishing stenter, dyeing machine, drying room, and mixing mill, etc. The needed temperature of textile process is 60~180℃. Sitong boiler developed a wide range of industrial boilers that could be used for textile industry.

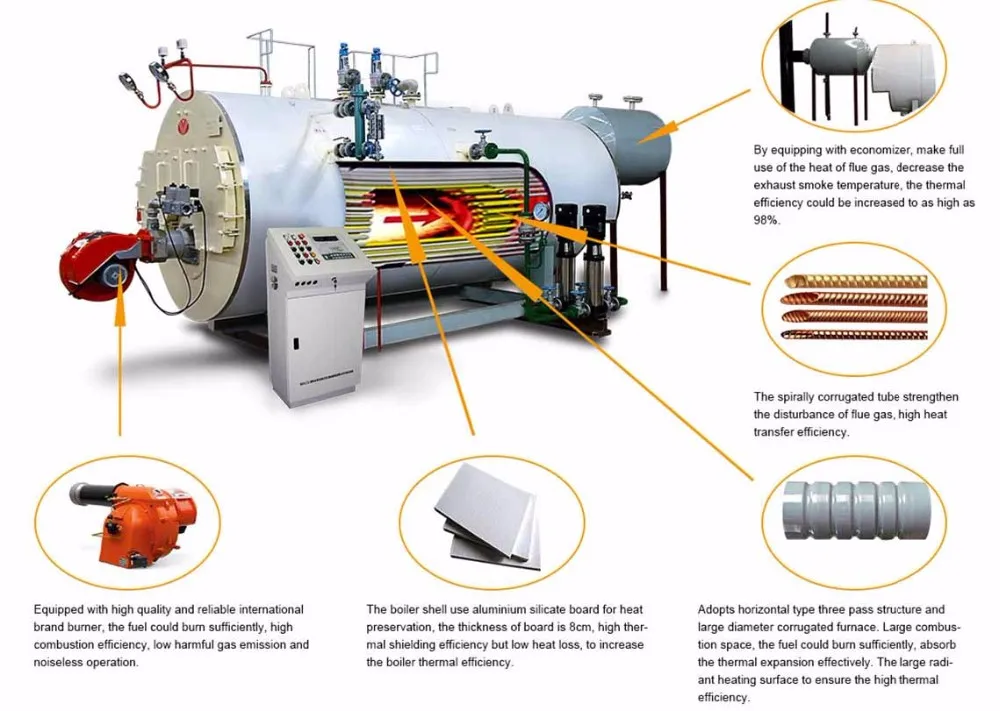

Sitong WNS series condensing gas steam boiler is an safe equipment with full automatic control system. It is the patent products of Sitong Boiler, the patent number is 2014 2 0504448.2. The condensing gas boiler for textile industry has wet back structure, it can adapt to the high temperature, has a good sealing, increase the radiation heat transfer area and improve the heat transfer efficiency. As a packaged fire tube boiler, it has the characteristics of compact structure and small size, strong load adaptability and low water quality requirement. By equipping with economizer, the thermal efficiency could reach as high as 98%.

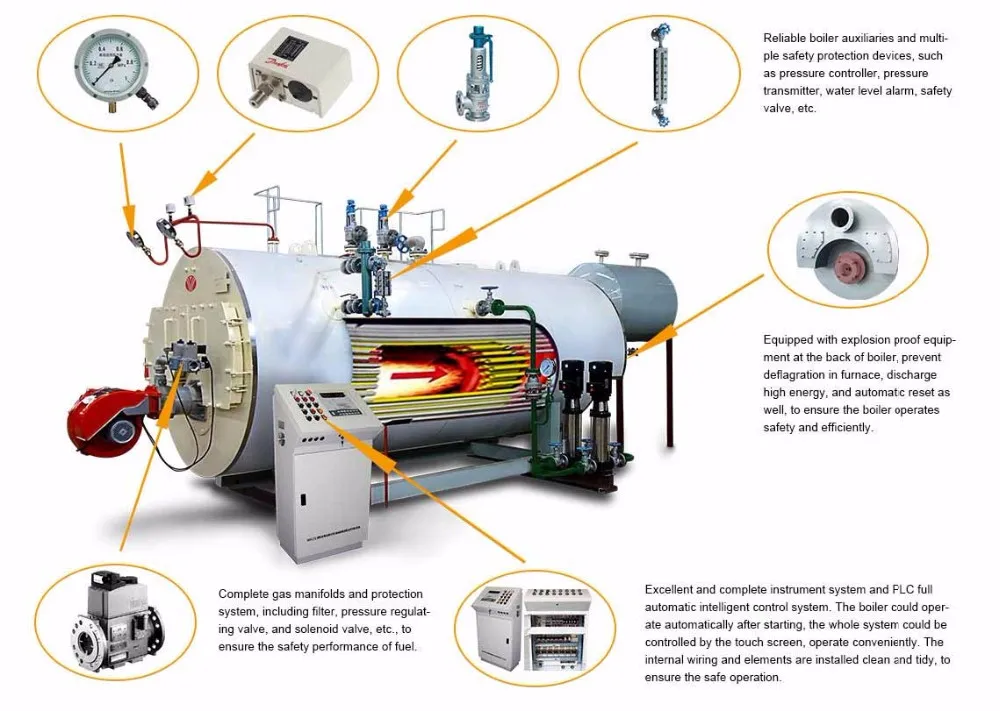

Safety Assurance of 150psi Condensing Gas Boielr for Textile Industry

Efficiency Assurance of 150psi Condensing Gas Boielr for Textile Industry

Automatic Protection Device of 150psi Condensing Gas Boielr for Textile Industry

1. Monitoring of water level

2. Setting time

3. Electric leakage protection

4. Water shortage protection

5. Power abnormal protection

6. Over pressure protection

7. Intergrated gas manifolds and protection system

8. Flue gas monitoring device

Technical Parameters of 150psi Condensing Gas Boielr for Textile Industry

Model |

Rated Steam Capacity (t/h) |

Rated Pressure (Mpa) |

Thermal Efficiency (%) |

Fuel Consumption |

Overall Dimension (m) |

Weight (t) |

Body Heating Area (m2) |

|

Light oil (Kg/h) |

Natural gas (Nm³/h) |

|||||||

WNS1 |

1 |

0.7/1.0 |

>90 |

66.5 |

75 |

3.6×2.0×2.0 |

4 |

25 |

WNS2 |

2 |

1.0/1.25 |

>90.2 |

133 |

150 |

4.8×2.5×2.46 |

8 |

60 |

WNS4 |

4 |

1.0/1.25 |

>91 |

266 |

300 |

5.8×2.85×2.8 |

13 |

113 |

WNS6 |

6 |

1.25/1.6 |

>91.5 |

399 |

450 |

7.25×3.1×3.15 |

19 |

181 |

WN8 |

8 |

1.25/1.6 |

>91.6 |

532 |

600 |

7.45×3.26×3.2 |

22.6 |

190 |

WNS15 |

15 |

1.25/1.6 |

>91.8 |

997 |

1125 |

8.7×3.7×3.5 |

34 |

346 |

WNS20 |

20 |

1.25/1.6 |

>92 |

1204 |

1418 |

10×3.6×4.0 |

45 |

467 |

Note: Parameter is for reference only, we can design the boilers based on customers’ needs. |

||||||||

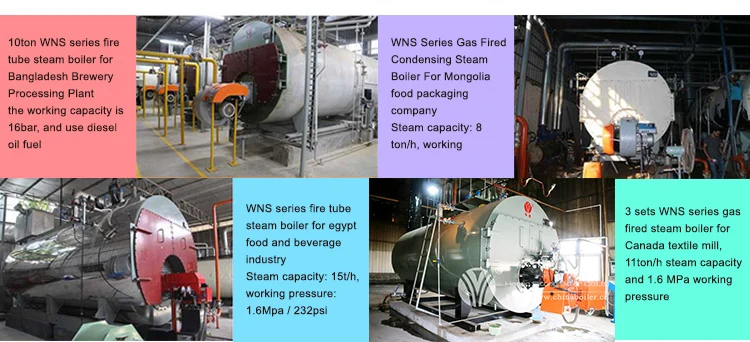

The WNS series Gas Oil Fired Steam boiler is shipping to Malaysia, customer use the Light Oil as the fuel, and use the boiler for his new Textile Industry.

Case of 150psi Condensing Gas Boielr for Textile Industry

Gas oil fired steam boiler is very popular, Vietnam customer uses it for the clothes factory, Ethiopia customers uses it for food processing factory, Bangladesh customer uses it for the milk processing factory, African customer use it for the wood processing factory, etc.

Business Exhibition of 150psi Condensing Gas Boielr for Textile Industry

Certification of 150psi Condensing Gas Boielr for Textile Industry

Warranty and after-sale service 150psi Condensing Gas Boielr for Textile Industry

Sitong promises the top quality of every set of machine and best after-sales service as followings:

(A)The boiler body guarantee is two years , for accessories three years.

(B)During the guarantee period , if the main body defective or broken without wrong operating, Sitong must replace the parts for free or prepare the spare-parts for free.

(C)Sitong should provide boiler technical service and operation guidance for whole life

long.

(D)Regarding to the installation and training , the buyer should take all the correlative charges(accommodation and food , round -trip tickets).