Brand Name: yongdga

Model Number: WZP-90

Place of Origin: Henan, China (Mainland)

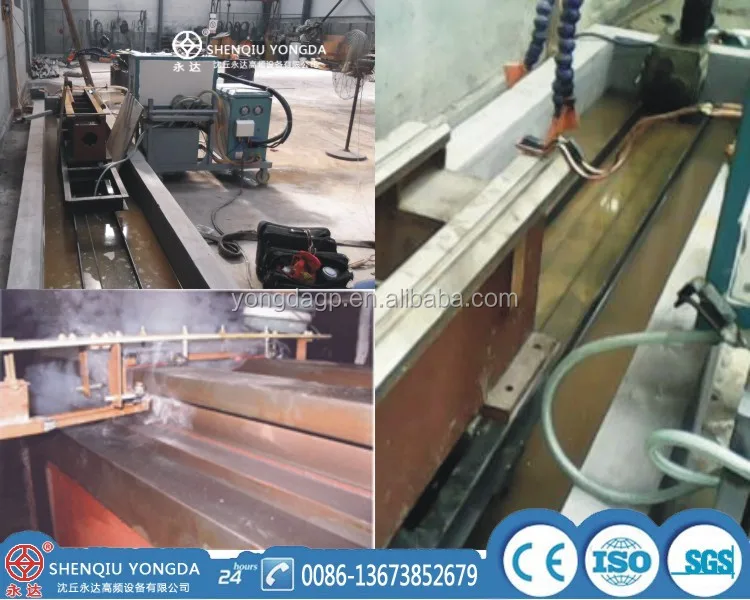

Supersonic frequency induction quenching slideway

Supersonic frequency induction quenching machine for quenching slideway, hardening layer is moderate, suface 1-3mm

Working onsite for quenching slideway

Applications of high frequency induction quenching machine

Hardening is mainly through the process of heating the workpiece material hardness of the metal after making changes.Specific applications are as follows:

1, various hardware tools, hand tools. Such as pliers, wrench, hammer, ax, screwdriver, scissors (gardening scissors) and the quenching;

2, Various automotive, motorcycle accessories. Such as crankshaft, connecting rod, piston pin, wheel, aluminum wheels, valves, rocker shaft, drive axle, a small shaft, fork, etc. quenching;

3, various power tools. Such as gear, shaft;

4, the machine tool industry . Such as machine tool bed, Machine Tool, etc. quenching;

5, various hardware metal parts, machining parts. Such as shaft, gear (sprocket), cam, clamps, fixtures, etc. quenching;

6, the metal mold industries. Such as small mold, die attachment, die quenching the hole, etc.;

Technical sepecifications of WZP-90 quenching slideway

Model |

WZP-90 |

Work power |

3 phase 380V+/-10%, 50-60HZ |

Input voltage |

320V-420V can be changed, depend on your country's electric power |

Input current |

6-90A |

Input power |

3-50KW(power adjusted stepless) |

Oscillation frequency |

10-50 KHZ |

Cooling water pressure |

0.2 MPA |

Size of geneartor: Transformer |

665*400*730mm 660*490*430mm |

Weight of generator ; transformer |

47kgs; 62kgs |

Water cooling protection point |

Below 50 degree celsius |

Quenching machine of our workshop

Technial parameters of quenching machine

Model |

Input voltage |

Input current |

Oscillation frequency |

Cooling water pressure |

WZP-40 |

320-420V |

2-40A |

15-30KHZ |

0.1MPA |

WZP-60 |

320-420V |

3-60A |

15-30KHZ |

0.2MPA |

WZP-90 |

320-420V |

4-90A |

15-30KHZ |

0.3MPA |

WZP-120 |

320-420V |

6-120A |

15-30KHZ |

0.3MPA |

WZP-160 |

320-420V |

6-160A |

15-30KHZ |

0.3MPA |

WZP-200 |

320-420V |

6-200A |

15-30KHZ |

0.3MPA |

WZP-300 |

320-420V |

6-300A |

15-30KHZ |

0.3MPA |

WZP-400 |

320-420V |

6-400A |

8-15KHZ |

0.3MPA |

WZP-500 |

320-420V |

6-500A |

8-15KHZ |

0.3MPA |

Features of quenching furnace

1, good energy efficient: high-frequency transistor can save more than 2 / 3than power;

2, special light,easy to move

3, low maintenance cost: no fragile, expensive tubes;

4, special security, no pressure, eliminating the high risk of electric shock;

5, high reliability: modular, integrated, high reliability assurance;

6, simple installation : just connect the power and water, and 10 minutes to complete.;

7, easy operation :a few minutes to learn.

Use cases of induction quenching machine

Gear quenching

Shaft qeunching

Crane wheel quenching

Packing of quenching machine

Wooden cases (plywood), one for packing generator, one for packing transformer, seperated packed.

1. Reply your inquiry within 24 working hours

2. Experienced engineer instruct and sales communicate with you in fluent English.

3. According to work pieces specifications, heating requirements, propose best solutions,also reference your ideas.

4. Machine details and working video link for your reference

5. Competitive price ,compare with the same industry

6. Production: strict quality standard, to produce machine and induction coils.

7. Debugging machine and only good machine will be sent.

8. Tracking goods shipping and provide bill of lading,invoice,packing list and other documents what you need

9. Provide install and technology instruction by sending drawings, email, or telephone,video.

10.If you need, will arrange one engineer to your place,instruct install machine and training operators.

11.Excess warranty period(12 months warranty), you can buy the spare parts from us with special discount price.

12.Provide long-terms technical support

If you have any metal parts require quenching, please do not hesitate to inquiry us,our experienced engineer will design a good machine model, coils, frequency suitable for your job.

Sincerely provide service for you!